Precision Machined. High Quality Gaskets.

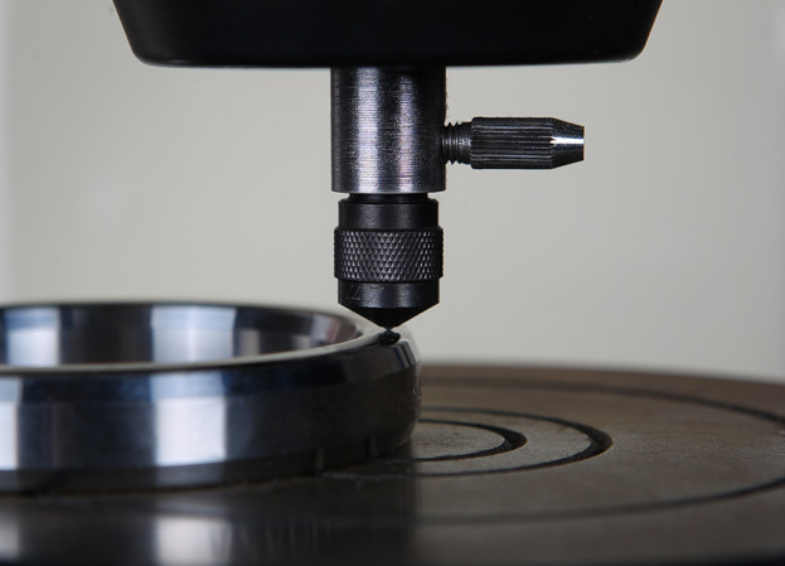

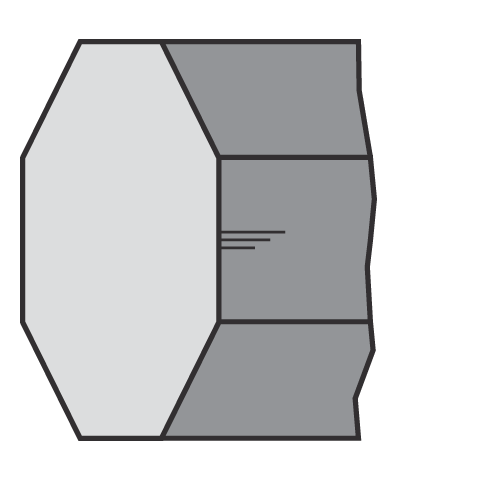

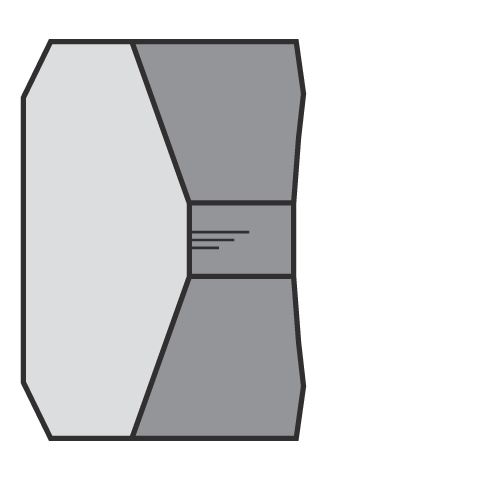

Ring Type Joint gaskets are precision-machined metallic gaskets. They are typically used in high-pressure applications such as the Oil, Gas, Petrochemical and Offshore industries.

This type of gasket is designed to be used in RTJ groove flanges and is produced under license to dimensions as per API-6A and ASME B16.20.

Contact Our Team